Excellence in Manufacturing

-

Raw Material

-

Sawing

-

Turning

-

Milling

-

Welding

-

Grinding

-

Electropolishing

-

Engraving

Raw Material

Our raw material stock includes rust and acid resistant stainless steel as well as high temperature resistant nickel-based alloys in the most common dimensions.

The re-stamping authorization according to DGRL 97/23/EG guarantees documentation according to regulations and ensures the traceability of the manufactured components.

Sawing

Our internal raw material-cutting starts every production process, whether cut to size or manufactured from bar stock.

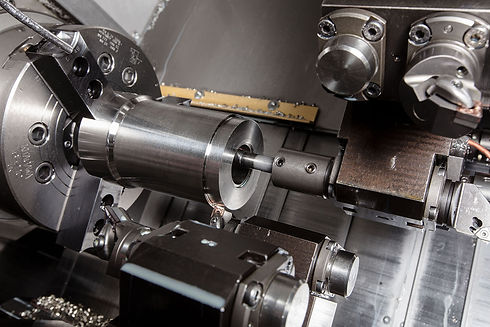

Turning

From simple 2-axis lathes to double-spindle turning and milling centers, we offer a complete range of manufacturing

possibilities.

For components outside of our machining

possibilities, we have a broad network of specialists at our disposal.

Milling

With modern 5-axis milling machines, coupled with our CAM system, we also master highly complex tasks, complex surfaces and geometries.

Welding

From simple welding work to pressure reactors with official requirements,

our highly qualified welders have the following approvals. EN IS0 9606-1,

EN287-1 / EN14732

Grinding

Whether bright metal, ground or polished, we deliver components with the desired surface quality.

Electropolishing

Electrochemical polishing and deburring significantly improves a number of properties of metallic surfaces. High-quality and functional surfaces for the most diverse requirements are achieved in a single operation. The removal takes place in the micro range and is reproducible with high accuracy.

Engraving

Depending on requirements and customer wishes, we can provide the manufactured components with a wide range of markings.

End control

By means of calibrated measuring and testing equipment, the components are checked for dimensional accuracy, shape, positional tolerances and surface quality and documented accordingly upon customer request.

Referenzprojekte